Maximizing Farm Biomas Efficiency for Power Generation

"It's [the farm bioproducts biodigester he built] sort of like a big cow stomach."

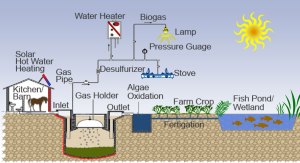

"The food that cows eat is not completely digested, so we break the manure down further with bacteria to crate methane gas, or biogas, that we collect and run through generators to produce electricity."

"If you grow conventional crops, it takes up a lot of land, and the land and machinery is so expensive. So smaller farms are getting squeezed out because they can't compete with larger farms that keep expanding [making it a requirement for those smaller farms to find a niche for themselves to remain productive and in business]."

George Heinzle, 56, Terryland Farms, Inc. St-Eugene, Ontario-Quebec border

|

| George Heinzle's biogas digester at Terryland Farms, St. Eugene, Ontario |

The end result is the production of electricity sufficient to provide power to up to 300 homes. The process requires roughly thirty days for the conversion from biomass into biogas, eliminating along the way odours generally associated with manure to the extent that what the output smells like cannot compare to the headache-inducing nausea of raw manure typically spread on farm fields. Power produced by the biodigester is sold to Ontario's power generator and distributor, Hydro One for 20 cents per kilowatt hour, giving the farm earnings of $20,000 monthly.

Fat and oil drawn out of the sludge, mixed with manure, creates additional gas ending up as more energy. The Heinzles also placed solar panels on their five barns, an additional manoeuvre to send electricity to the power grid, from which they derive additional income selling that source of power for 70 cents/kWh, a return that varies of necessity by the season, where in the warm sunny months they can depend on a monthly return between $12,000 to $13,000, whereas in the cold months that is reduced to $1,200 to $1,500 monthly.

In addition, the biodigester generates heat from the two engines driving it, and that heat is used to heat the family home, to provide hot water, and to dry corn in the fall. The Heinzles save money on utility costs by producing their own power, and on fertilizers as well, since the biodigester produces digestate, converted from the raw manure, which spread on soil provides organic content and helps in retention of moisture. As well, his milking cows sleep on pasture mats; undigested fibres processed by the biodigester, as bedding.

The cost to the Heinzles to set up the biodigester and solar panels on the farm came to over $2-million as an investment in their enterprising power generation system. They have now recouped that investment thanks to revenues from electricity sales; the farm turns a profit through dairy products, small crops of soybeans, corn and wheat, as well as the generation of electricity. Rather than sending their harvested soy to a mill, the farm processes its own into soymeal pellets for cattle feed, extracting oil from the beans in the process, for use as tractor fuel.

Terryland Farms is the first in Ontario to launch this clean-technology concept. Manure produces methane, converting cow dung into biogas, but the process used by the farm reduces methane emissions, thus cutting one-third of farm-related greenhouse-gas emissions. And instead of sending waste to landfills, the farm uses it in its electricity generation. As the first Ontario farm set up to produce and sell electricity for a profit, it acts as a spur to other enterprising Ontario farmers to convert their disposable waste to energy as well.

Throughout eastern Ontario an estimated 15 additional farms are now in the process of beginning their own similar enterprises to convert biogas into electricity and providing it for the grid as an environmentally friendly saleable resource.

Labels: Biodigester, Farms, Ontario, Power Generation

0 Comments:

Post a Comment

<< Home